2019-07-16

1363

"Aluminum Industry Expert 10.0 - Group Version" is the latest platform product developed by Haotai Technology Co., Ltd. The product adopts a new startup platform architecture, which has been developed and perfected for more than six years since 2013. It has become mature and successfully applied in the 10.0-group edition of aluminum industry experts. "Aluminum Industry Experts 10.0-Group Edition" has accumulated a large number of research and development experience and project implementation experience of products such as "Aluminum Industry Experts 9.0" and "Aluminum Industry Experts 9.5". It has realized the rapid development and construction of modules, greatly shortened the time of secondary development, can respond to customer needs faster, and shorten the project on-line time. At the same time, fields, functions and reports can better achieve customization and achieve real special edition.

"Aluminum Industry Expert 10.0-Group Edition" is a set of large ERP group management system, which includes group management, sales management, production management, warehouse management, BI report management and so on. It realizes the systematic management of the whole group in series. Among them, group management, BI report main service decision-making leadership, sales management, and so on. Through data analysis, production management and warehouse management provide decision-making basis for group leaders. Sales management mainly serves the sales companies and provides the most direct operation platform for the daily work of the sales companies. Production management serves each production plant and feedback the production situation in real time. Warehouse management serves all warehouses, realizes fast and accurate warehousing and outgoing work through bar code management, and provides strong guarantee for the authenticity of inventory data.

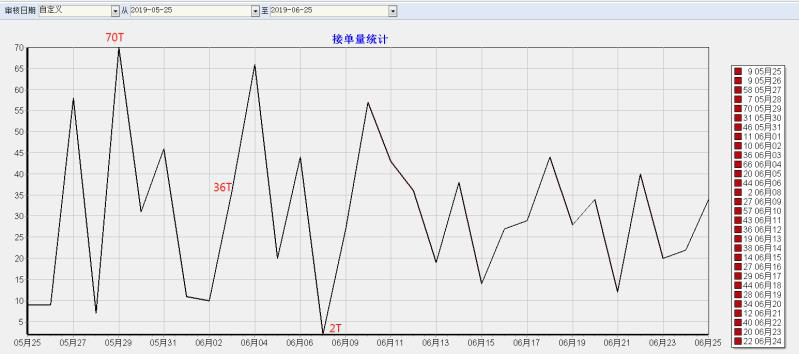

The following is the order quantity statistics chart

Company Profile.

Foshan Junfuxinye Metal Material Co., Ltd. is a large-scale comprehensive enterprise specializing in the production and processing of aluminium profiles. It is located in Foshan, the largest and most perfect aluminium profile production and marketing distribution center in China, and the industrial base of aluminium profiles in China. The company has strong technical force, with advanced domestic aluminum profile production line, from casting - die opening - extrusion - surface treatment - forming - oxidation, electrophoresis, spraying - packaging one-stop service. Products include all kinds of industrial aluminium profiles, doors and windows aluminium profiles, aluminium profiles accessories, radiators, aluminium profiles frame, decorative lamp box aluminium materials, electronic products shell aluminium materials, kitchen cabinet furniture partition aluminium materials, shower aluminium materials, poster advertising photography aluminium materials, display aluminium materials, automatic sunshade aluminium materials, etc.

Foshan Junfuxinye Metal Material Co., Ltd. is a group enterprise integrating sales, production and warehouse. There are some problems in its operation and management. So how to solve the problem of enterprise management through "Experts in Aluminum Industry 10.0-Group Edition"?

1. Overview of Process

The group set up a special order center to receive orders, and then allocated the order center to different profiles processing plants for production.

After processing, it is transported to the relevant warehouse for storage according to the actual situation, and then shipped and sold by the respective sales companies.

2. How does the system solve the enterprise problem?

1. In the initial stage of an enterprise, the order allocation order relies on manual fax, which often results in information faults and leaks of production.

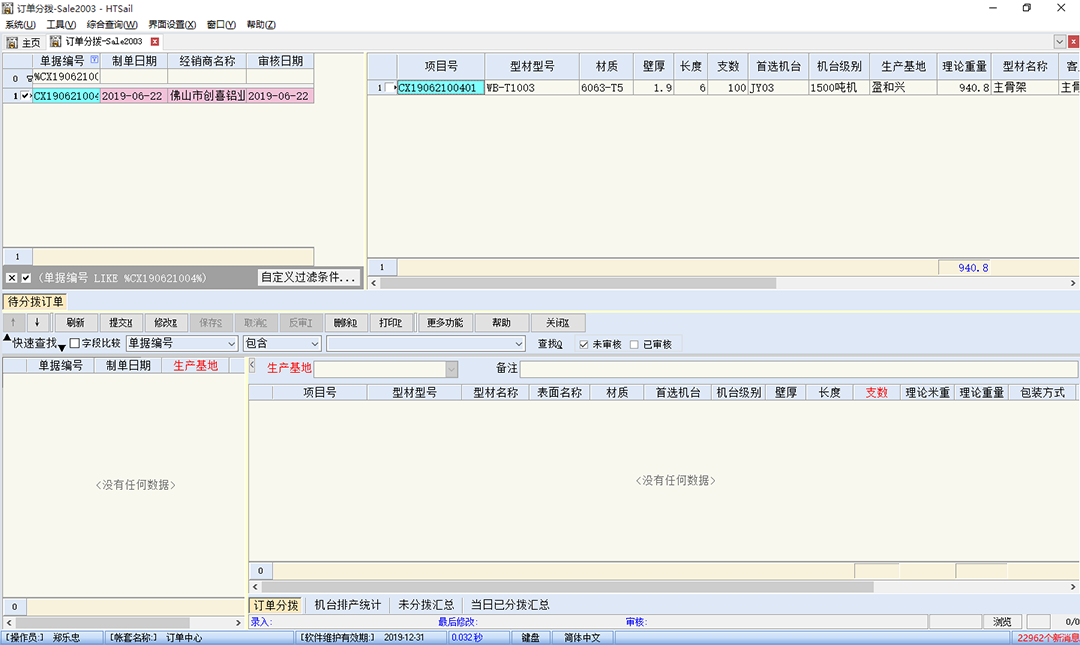

Answer: In view of this situation, the system specially establishes an order allocation function, each processing plant can only see its own order allocation. Scheduling and production according to the order can thoroughly solve the production chaos.

2. There is a disconnection between the sales company and the production before the system is used. The production information can not be transmitted to the sales company in time, which leads to the phenomenon that the sales can not be delivered in time.

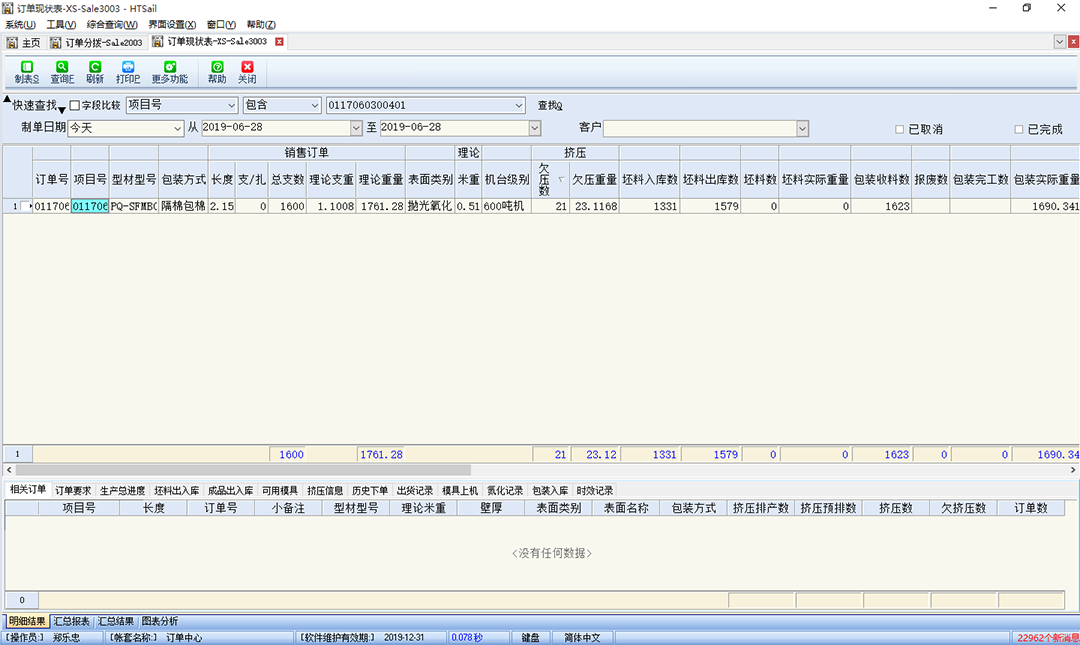

Answer: The system adds an order production schedule to the sales management, which can pay close attention to the production situation at all times and solve the problem that the information between the sales company and the processing plant is not interoperable.

3. When delivering goods, the company often makes mistakes because of the problems of human or similar products, which affects the image of the company.

Answer: The system uses automatic printing label after packaging. The label has a unique barcode identification and a sketch of the product. The whole warehouse realizes barcode entry and exit to solve the problem of wrong shipment.