2019-08-09

1182

One. Introduction of Gaodun Metal Co., Ltd.

Foshan Gaodun Metal Co., Ltd. was registered in Sanshui District, Foshan City, Guangdong Province on November 01, 2016. The address is located at No. 22, D District, Sanshui Industrial Park, Foshan City.

The company's business scope: metal and metal ore wholesale (excluding hazardous chemicals); building materials wholesale; aluminum rolling processing; metal doors and windows, forgings, powder metallurgy products, traffic signs manufacturing, non-ferrous aluminum products, strict control of quality .

Second, the main implementation module

This high-Shield Metal Co., Ltd. "Aluminum Industry Expert 10.0" ERP project online module has:

Third, the main stage of implementation

The ERP project of the high shield metal "Aluminum Industry Expert 10.0" will be accepted from May 27, 2019 to June 15, 2019. Under the joint support and care of both leaders, the high-shield ERP project team and the technical staff of Haotai Company completed the project start-up, basic data preparation, implementation plan, system software installation and field research under the efforts of the implementation engineers. Phased tasks such as system training, system on-line, and acceptance of problem processing are completed on time in the 18-day period of each phase of tasks and unexpected transactions.

Fourth, problems before the implementation of the project

1. Before the switchover, the original process has a variety of operation modes (such as: manual single, old system, inaccurate data due to process). The old system has many operation steps and difficulties in scheduling, which causes a lot of trouble for the operator.

2. Some extruders are unable to use the old system, and the arranger needs to issue two different machines in the old system and paper scheduling. Some machines use manual paper documents for recording, and super-production is very common.

3. Aging and transfer warehouses There are two types of paper and system due to the inflow of documents in the process. The original aging does not have a pounding process, so there is a great difference in the weight of the warehouse and the weight of the production.

4. It is very complicated to order the finished product warehouse and find the over-production inventory. The customer can't reply to the customer's order status in the first time and is very dissatisfied with this customer.

Fifth. Project implementation results

Under the implementation of the engineer's expertise and tough business capabilities, the project successfully completed the switching of the new system. In the initial stage, due to the error in the data provided by the customer, the system process was cut off in the initial period of the system process, and all the problems encountered before the customer did not switch the system were treated with the best and fastest, and the customer was consistent. Satisfied with praise. Both parties agreed that the project has achieved the goals of data sharing, data circulation efficiency, process control, easy operation and system accuracy, as follows:

Outstanding contributions from "Aluminum Industry Expert 10.0":

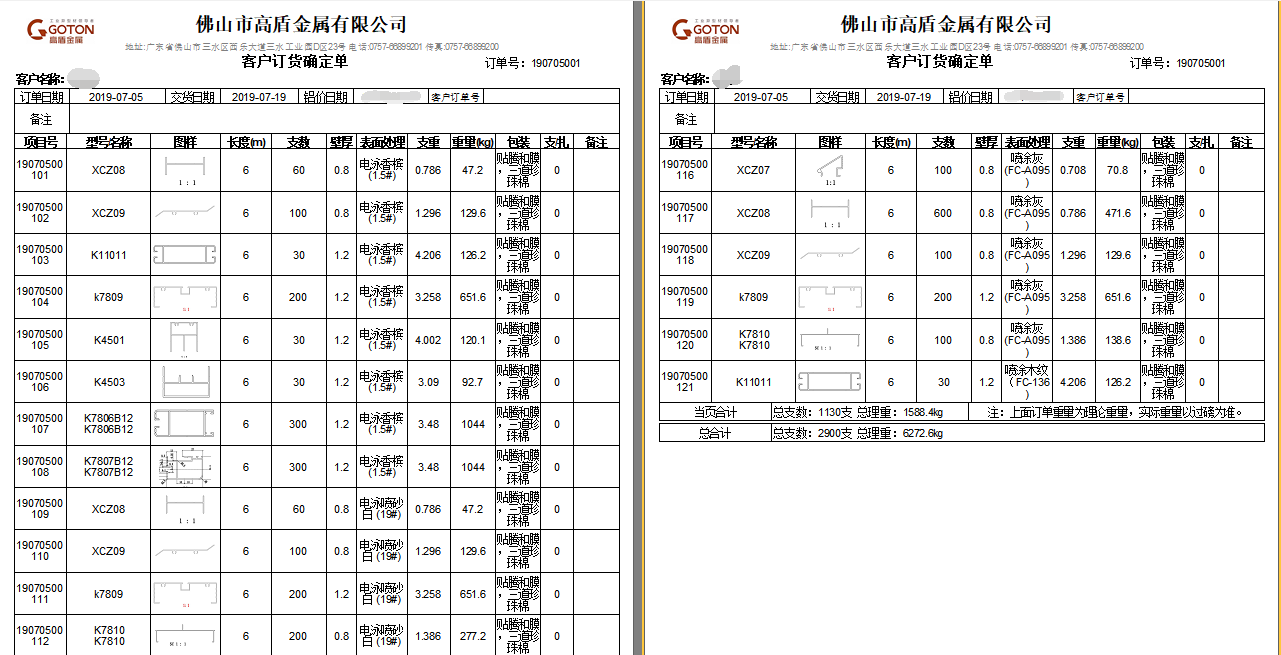

1. In order to achieve the reliance of the high shield metal customer on the original sales confirmation form, the sales order style is modified. The other customer's response to the original order confirmation form has no sketches. It is necessary to check the paper sketch again every time, so the new sketch query is effective. Increased customer efficiency in confirming orders.

2. The original customer asks the orderer about the status of the order. The follower needs the inquiry from each department to respond to the customer. Therefore, the customer is not satisfied with this. After switching the new system, it is recommended to use the order status table, sales order summary, and production status table. This problem has effectively improved the customer's satisfaction with the high shield metal and the efficiency of the merchandiser.

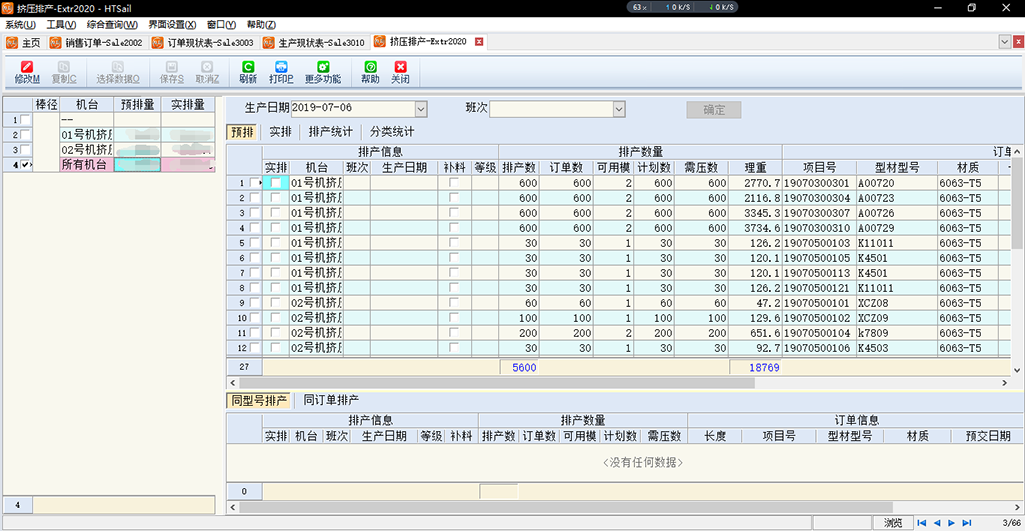

3. The scheduler is familiar with the use of 'extrusion scheduling list' and the production is very convenient. The scheduling staff has greatly improved the scheduling by using the scheduling statistics, classification statistics, the same model scheduling, and the same order scheduling. The accuracy and averageness of the semi-automatic production after familiarity with the use of 'extrusion scheduling single' can be scheduled in advance.

4. Abandoning the original part of the machine needs to be used in the form of manual orders for production and production, greatly reducing the operation of the machine squad leader in order to focus more on production. The subsequent operations were unified on the data.

5. Improved the problem that the original outsourcing needs to rely on the transfer warehouse to rely on the order surface to distinguish whether it is out of order. Because the characteristics of the process control of the system are solved, the warehouse manager can not confirm the actual quantity when the warehouse is out of the warehouse, so the scheduler can replenish the outsourcing orders in a timely manner.

6. Reduce the difficulty of operation in the packaging workshop and improve the efficiency of the packaging staff. Under the determination of both parties, the original label of the customer was modified, and the promotion of the customer label was improved.

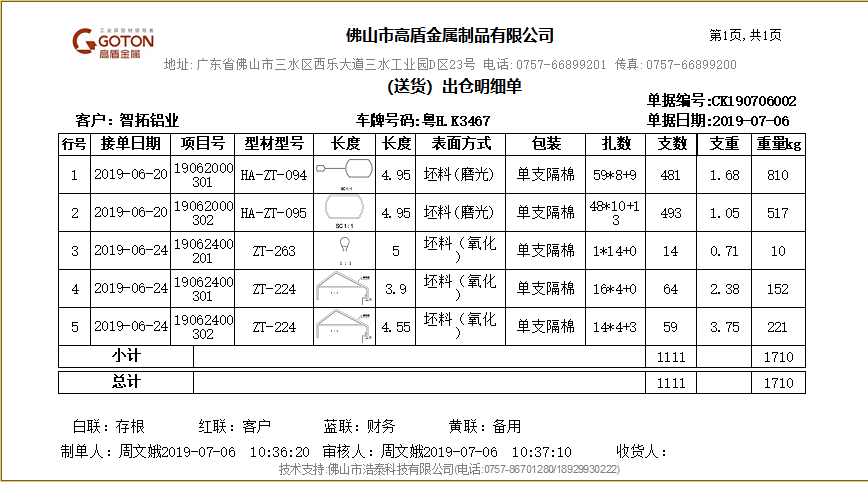

7. Dealing with the problem of frequent seasoning and order transfer of the finished product warehouse, the information of the ordering personnel to specify the order quantity, etc., and then the finished product warehouse personnel use the finished product adjustment to make the order. Change the original sales warehouse receipt, add the sketch in the aluminum ingot price field for financial accounting and customer confirmation orders (because the financial use of Kingdee financial system, with the agreement of both parties, Gaodun Metal has not activated the "Aluminum Industry Expert 10.0" financial module ).

8. Compared with the "Aluminum Industry Expert 10.0", the management efficiency of the process is improved, and the high-shield metal is well-organized from the original operation mode and data confusion, realizing the data transmission and reducing the operator. The burden is to improve the accuracy of the data. Powerful to make customers more trustworthy, dynamic and flexible modification rights in report design and help customers to recognize the stability of the system.

Sixth, the reason for the success of the project

The success of the implementation project benefits from the following points:

1. The leaders of both sides attached great importance to the project and supported the work of the ERP project, especially the high-level leaders of Gaodun Metal attached great importance and support to the ERP project.

2. The initial accommodation problem was also solved the fastest way with High Shield Metal, without delaying a lot of valuable time.

3. Haotai Software Company's professional implementation, technical staff's strong help.

4. The ERP specialists actively cooperate and follow up, and the operators of the various departments maintain communication at all times;

The active cooperation of the operators of various departments has a crucial relationship with the implementation progress.

The success of the implementation has a great relationship with the direction of each person, hard work and hard work.

Seven, continuous support

After the acceptance, only the next phase of the project is planned to be maintained. The acceptance is only a phased summary of the project. This does not mean that the cooperation between the two parties ends, but this is the beginning of a new phase. The expansion of the Gordon metal will continue to improve the use of ERP, Haotai Technology will continue to provide technical support for the continuous optimization system for the end of the high shield.