"Aluminum Board Expert" is the latest ERP product developed by Haotai Technology Co., Ltd. It relies on many years of in-depth understanding of the aluminum processing industry to provide professional ERP management software tailored for board, belt and foil manufacturers. After 13 months of research, development and implementation, the "Aluminum Board Expert" officially matured, its simple and user-friendly interface, combined with the workflow production management mode, effectively optimize the task release and production process control Finally, it will solve the blind spots in the management of production processes of enterprises, and bring the gospel of information management to the production enterprises of plates, belts and foils.

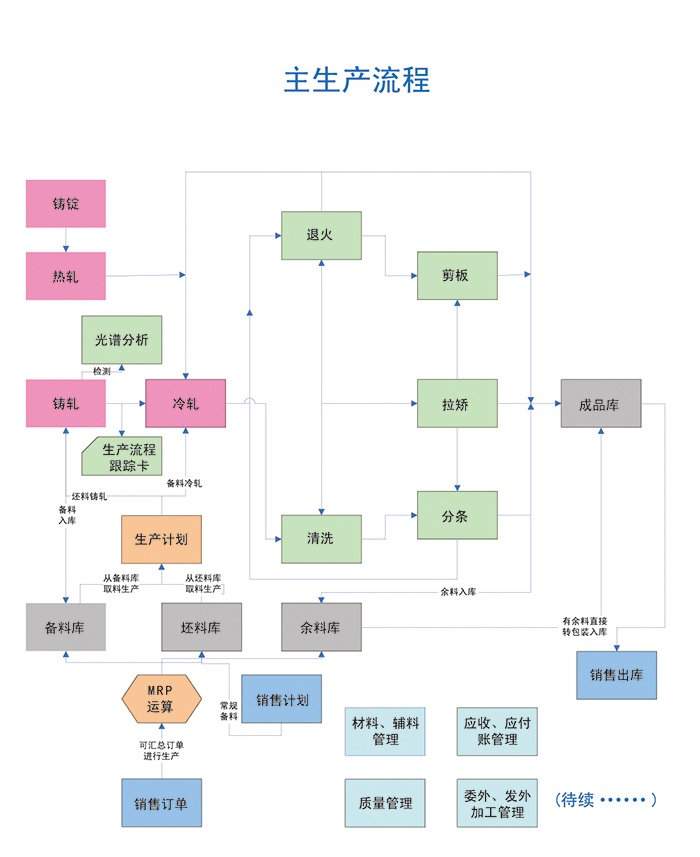

"Aluminum Board Experts" covers "basic materials", "casting and rolling management", "order management", "production planning management", "hot rolling management", "cold rolling management", "annealing management", "cleaning management", " Pulling management", "strip management", "table management", "board management", "outside management", "foreign management", "material warehouse and related management", "quality management", "acceptable Coping management, "question silo", "blank bin", "reservoir bin", "reservoir bin", "waste bin", "report system"... At the same time, "aluminum plate expert" for enterprise remote monitoring And the strong joint mode, the application is based on the B / S architecture development, from now on the Internet and have the relevant you, you can always know the real-time situation in the factory.

The product development process guarantees product quality through five steps of development, development, self-inspection, testing, implementation confirmation, and customer acceptance.

The service system is guaranteed by the five parts of field research, demand research and development, station implementation, acceptance and regular door-to-door maintenance.

Product positioning: domestic large, medium and small plate with foil production enterprises, group management enterprises.

Scope of application: aluminum, steel plate and foil production enterprises

Group management

According to the organizational structure of the Group's industry, it will quickly build a professional information system for each of its subordinate industries to achieve rapid development of various industries and the purpose of the Group's overall management;

According to the group information level management, fine management is achieved through careful permission setting.

Improve business processing efficiency

The information on the available inventory, the production capacity of the workshop, etc. when the order is received is reflected in real time, and the quick order is realized.

After the order is received, the production process tracking is meticulous and clear, and the business is in control of the production progress.

Efficient scheduling and increased production capacity

With flexible production process settings, production guidelines are automatically formed in process order.

The work production management mode is used to effectively optimize the planning department's task release and production process control, so that the production process is simplified and linearly managed.

Super detailed production process reports, meeting the status of workshop handover, production tracking progress and quality process control requirements.

Analyze the aluminum coils that can be used for production based on current stocks prior to production.

Improve quality and control costs

Quality problems in the production process are tracked and intercepted in time to reduce waste of working hours and reduce losses.

Inventory and historical stock

Independent inventory management, sub-batch silos, stock silos, residual silos, problem silos, scrap bins and hardware accessories material silos, to achieve different material properties for sub-storage management requirements.

Complete historical inventory tracking to view inventory data at any time.

Real-time reflection of the current occupied inventory, to avoid the phenomenon of "grabbing".

Analysis report

The production schedule is monitored by flow, and the abnormal situation responds quickly.

Extend information throughout the system, and quickly check the status of the project anywhere.

Powerful right-click function to customize the generation of statistics or summary reports.

Implementation process

Project preparation

Preparation before the project is officially launched (project confirmation, project handover, project start-up meeting)

Project planning

The implementation consultants have a detailed understanding of the customer's business processes, and have determined the customer's implementation plan to achieve the customer's blueprint (business needs research, research needs summary analysis, basic data collection and preparation, implementation plan establishment and evaluation).

Implementation of the initial stage

The implementation consultant performs system configuration, data collation and testing based on the implementation of the survey results and implementation plan (basic data import, system configuration, system flow test, printed form design)

Project implementation

Full implementation of the system to achieve the customer's ideal blueprint (user training, user operation manual, preparation of relevant ERP management system, authority planning and distribution, formal launch, on-site guidance and supervision, use of customer function adjustment, close communication with customer executives.)

Project Acceptance

Realize the customer's ideal effect and use status assessment (collect the use information of each department, project acceptance, continuous technical support, maintenance cooperation)