2019-07-16

1356

Established in 2005, Xinjiang Yuansheng Science and Technology Development Co., Ltd. is the oldest, largest and most market-occupied leading private aluminium profile manufacturer in Xinjiang.

The company is located at 786 Lantian Road, Industrial Park, North District of Urumqi High-tech Development Zone, Xinjiang. It covers 120 mu of total area and has a construction area of nearly 50,000 square meters. It has more than 600 employees. It has the leading ABD automatic vertical powder spraying production line and 14 automatic extrusion production lines in Xinjiang.

The company produces and manages six categories of building aluminium profiles, decorative aluminium profiles, industrial aluminium profiles, solar energy aluminium profiles, such as "Yuantai" brand anodic oxidation, electrophoretic coating, fluorocarbon paint spraying, powder spraying, wood grain transfer printing, bridge insulation, etc. The company has obtained ISO 9001 quality management system certification and ISO 14000 environmental management certification, and has implemented strict quality management system.

In 2014, the "Yuantai" brand aluminium alloy building profiles produced by the company were selected as "Xinjiang Famous Brand" by the Brand Strategy Committee of Xinjiang Uygur Autonomous Region.

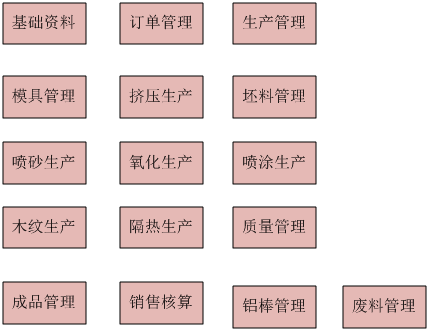

2. Major Implementation Modules

The ERP project of "Aluminum Industry Expert 10.0" of Yuansheng Technology Co., Ltd. involves on-line modules:

3. Main stages of implementation

Yuansheng Science and Technology "Experts in Aluminum Industry 10.0" ERP project started on April 6, 2019. With the strong support and concern of Yuansheng Science and Technology and the leadership of Haotai Software Company, Yuansheng Science and Technology ERP project team members and Haotai company implementation engineers have worked hard to complete the project start-up, system installation, business research, and basic capital successively. Material preparation, standard training, scheme determination, training switchover online, acceptance problem processing and other phased tasks, the project lasted for 2 and a half months, and the work of each phase was completed on time.

4. Problems Existing before the Implementation of the Project

1. In the system and actual logistics that are in use before switching, pre-processing bills are very frequent, finished warehouse bills are relatively frequent, and the production links after extrusion are not produced, tracked and circulated according to orders. As a result, logistics is not smooth.

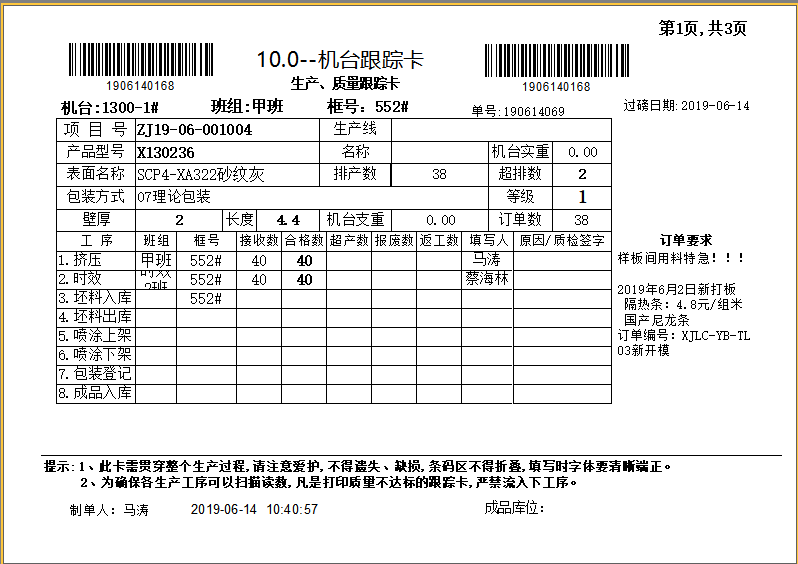

2. Extrusion overscheduling is serious. Only one accompanying card is printed in many colors. After adjusting the frame, the extrusion tracking card is messy. The oxidized upper carriage accompanying card is not transferred to the oxidized lower carriage. No accompanying cards are sprayed on the lower carriage. The packing workshop does not pack according to the order and the materials of the same order are not put together. The evening packaged materials were not stored in time and piled on the ground instead of on the car.

3. The control function of the planning department is relatively weak. The pre-switching extrusion is scheduled by the extrusion workshop itself, not by the planning department. This new system is quite different from the old one.

4. When printing the amount of fluorocarbon, stretch bending and rubber strip, we need to click on a variety of printing styles. It is easy to forget the amount of printing. It is very troublesome to deal with the amount again and easy to cause direct losses.

5. Project implementation results

In Haotai, engineers have rich experience in system on-line, excellent business capability, no data problems and production obstacles in the process of switching between old and new systems, which is over-stable. After nearly two months of implementation, the old system can be completely disabled except for a small amount of old stock. Although there are many difficulties in the implementation of the project, under the understanding and cooperation of Yuansheng Science and Technology and Haotai Software Company, Yuansheng Science and Technology's business operation is basically smooth, and the complete data flow of the enterprise is realized in the system. Both project implementation teams agree that the system can run steadily. The timely transmission of information has achieved the goals of data standardization, business process standardization and information sharing. The specific effects are as follows:

Outstanding contributions of the new system:

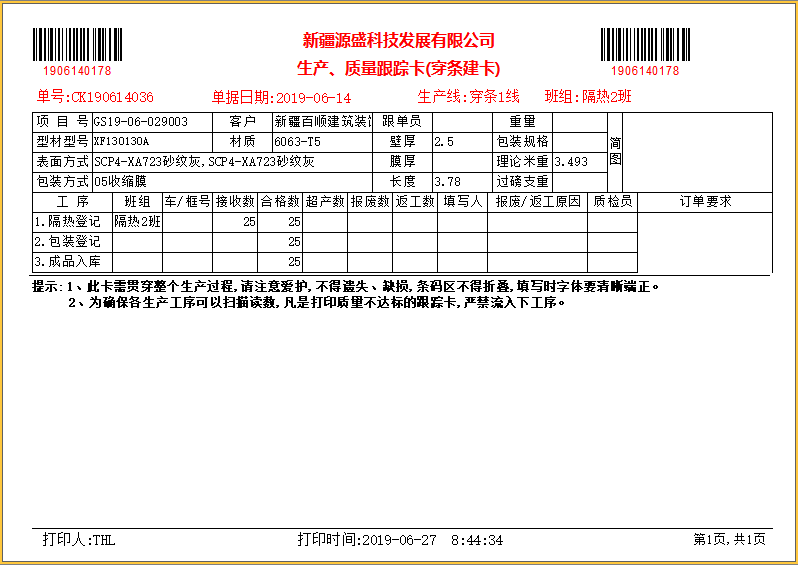

1. It solves the problems of smooth logistics, production links not producing, tracking and circulation according to orders. Specific effects are as follows: barcode tracking cards with bars, spraying and wood grain are tracked to the finished product warehouse; oxidized and electrophoretic materials are printed on the shelf until the finished product warehouse is tracked to the finished product warehouse; insulated main materials are registered and printed barcode tracking cards until the finished product is stored in the warehouse. The production realizes sweeping code and making orders, which makes the data cohesive and traceable.

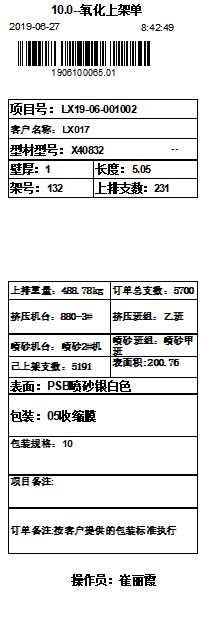

2. The monitor makes the list. Sweeping cards is simple and accurate. Aging, sand blasting, vertical spraying on the shelf, and wood grain registration are all the operation of squad leader.

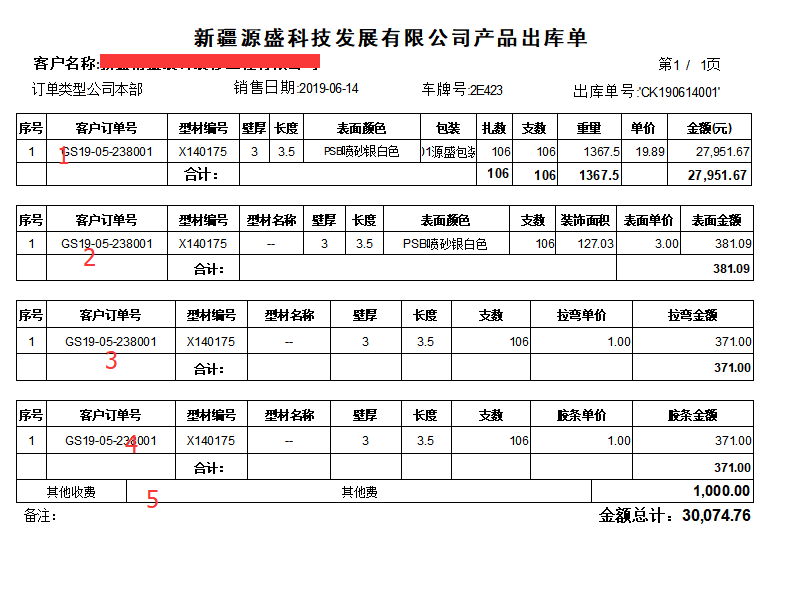

3. Solve the problems of single fluorocarbon, stretch bending, tape and other price forgetting to print. In the past, if it is fluorocarbon material, you need to click on [fluorocarbon printing style] to print the amount of fluorocarbon, if it is stretch bending material, you need to click on [stretch bending printing style] to print the amount of stretch bending. If the fee is charged, you need to click on [stretch bending printing style] to print the amount of stretch bending, which is easy to miss typing. 10.0 Sales Accounting Single Printed Report, according to the content of the documents, automatically detect, if there is a amount of fluorocarbon, automatically increase the printing style of fluorocarbon, if there is a amount of stretching, automatically increase the printing style of stretching, if there is a amount of sticking, automatically increase the printing style of sticking, if there are other amounts, automatically increase the printing style of other amounts. Printing style, never miss typing.

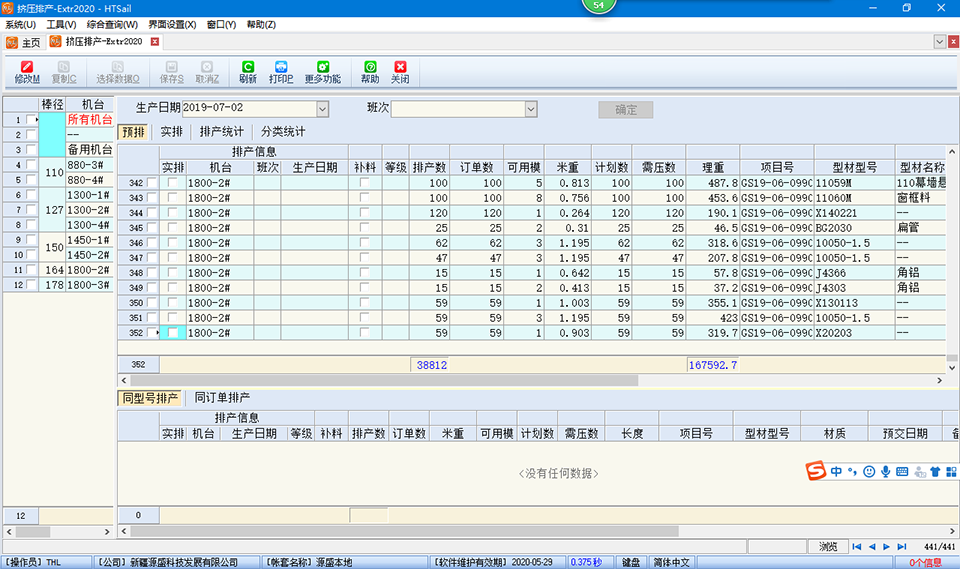

4. Extrusion scheduling deals with multi-shift scheduling, single-row scheduling, batch scheduling and the same type scheduling.

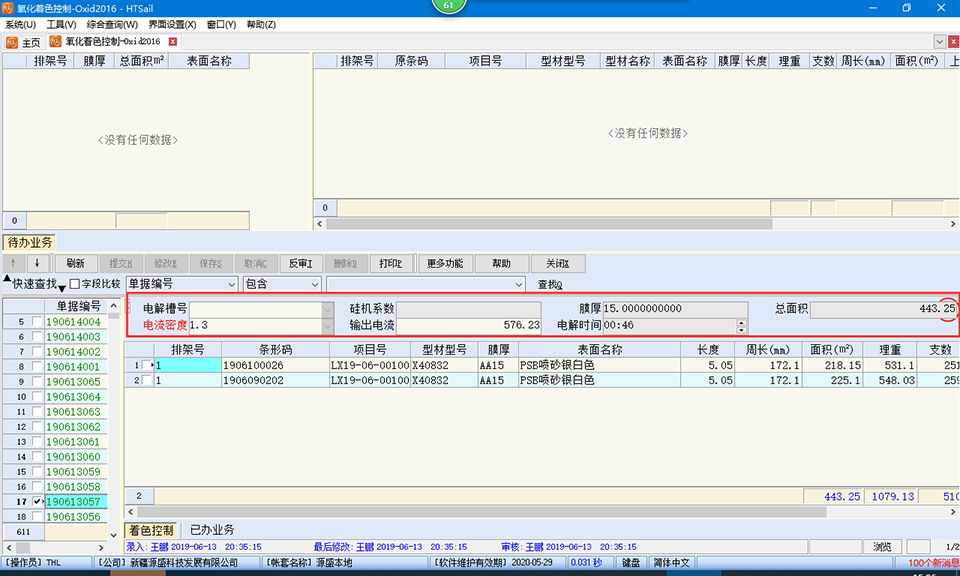

5. Oxygen coloring control, easy to operate, automatic calculation of total area, current and time.

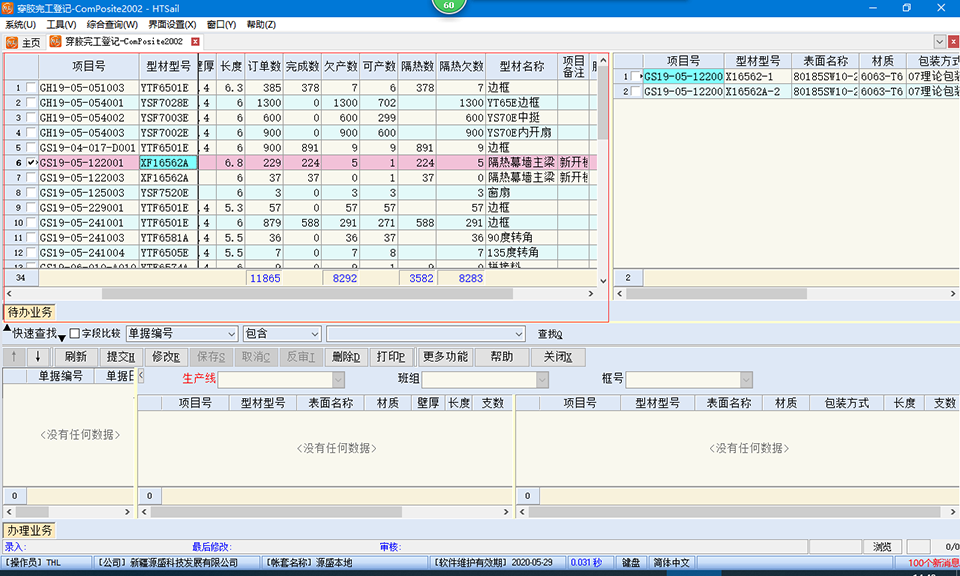

6. The new system solves the management of insulated semi-finished warehouse. The top left table can clearly see the number of matched insulating profiles, such as orders, finished products, under-stocks, heat insulation, under-stocks, order notes; the top right table can clearly see the number of semi-finished insulating profiles.

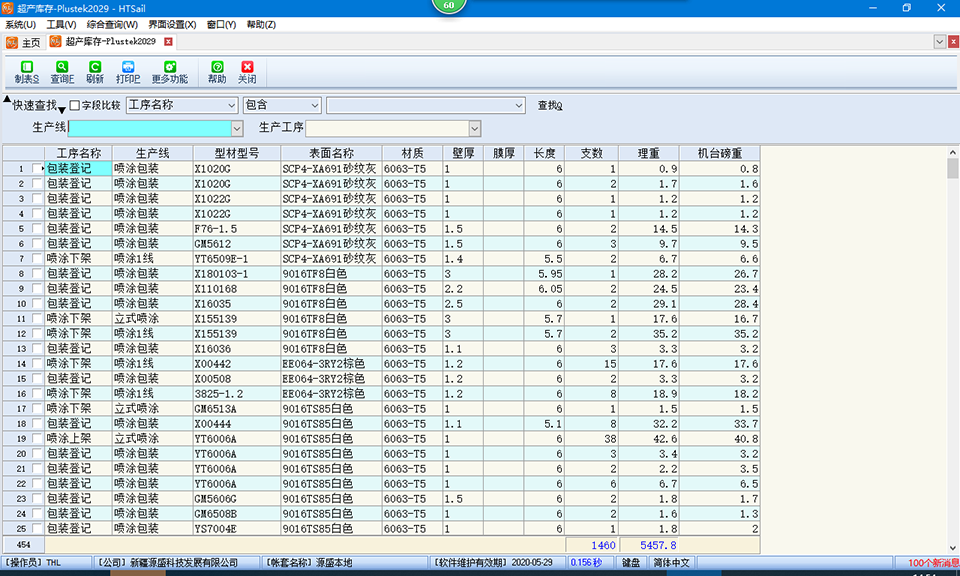

7. Over-production material registered in each process can automatically generate over-production stock, which can be seen at a glance:

8. Handled the problem of frequent seasoning and bill of lading in finished warehouse. (Processing plan: orders beyond a certain period of time can be transferred; original customers can only take the remaining goods or place new orders if they want to take delivery of the goods after the transfer order; finished warehouse shipments are sent to new customers according to the original project number, and the price problem returns to the sales department; because the problems caused by the change of the order are returned to the sales department to deal with themselves, so that the system can be controlled. Frequent monotony in Tongzhong.

9. It took nearly six months for the old system to go online. Compared with the old system, the successful implementation of this project fully embodies the advantages of Haotai software platform development, greatly shortens the development cycle of demand, system updating is more efficient, high stability provides a strong guarantee for customer business adjustment. This is an advantage that the old system can't match. The flexibility and expansibility of the new system report fully embodies the advantages of the new system report.

6. Reasons for Project Success

The successful implementation of the project benefits from the following aspects:

1. The leaders of both sides attach importance to the project and give strong support to the ERP project work, especially the senior leaders of Yuansheng Science and Technology attach great importance to and give strong support to the ERP project work.

2. Yuansheng Science and Technology Departments are actively cooperating with each other in the same direction; the relevant operators are actively cooperating with the ERP work and hard work; the Ministry of Technology actively goes to the workshop to collect and deal with problems, arrange courses and operation rules, so as to create more benefits for the implementation of engineers to meet the development needs of enterprises and bring more benefits to enterprises. Conditions are met.

3. Yuansheng science and technology accommodation and other logistical support, so that the implementation of engineer services enterprises without worries;

4. Haotai Software Company's professional implementation consultant team, strong technical support.

Continuous support

Acceptance and acceptance of project implementation is only a stage summary, which affirms the work results of the team members of both sides. The promotion and deepening of the use of ERP is endless. Yuansheng Science and Technology will continue to improve and deepen the use of ERP.

Project acceptance does not mean the end of cooperation between the two sides, but marks the beginning of a new stage of cooperation between the two sides. Haotai will continue to provide technical support services such as continuous optimization and application for Yuansheng Science and Technology. After acceptance of the system, it has entered the stage of operation and maintenance. The implementers and technicians of Haotai Company continue to be responsible for the support and maintenance work in the future according to the contract.