2019-08-09

1274

First, customer profile

Foshan Shendamei Special Aluminum Alloy Co., Ltd. is located in Foshan City, Guangdong Province, one of China's most economically powerful and developmental vitality. It is a large and medium-sized enterprise integrating R&D, processing, production and sales. The company is specialized in the production of aluminum alloy industrial profiles and famous brand enterprises with strong regional strength and brand name. The registered trademark “Shenmei Te Aluminum” brand alloy profiles enjoys a good reputation both at home and abroad.

Second, the importance of ERP enterprise management system

A company with a mature and healthy ERP enterprise management system and a sustainable management mechanism can push the enterprise to the next step. Through accurate and timely information transfer, we will focus our efforts on the same direction and operate and manage the company in a workflow perspective. In this case, especially in response to market sales, lean production, and the use of industry advantages, we can form an unprecedented and deep cooperation, and work together to meet customer needs and win the market.

ERP enterprise management system is a management system with various resource planning optimization management as the core. It regards the production, operation and sales of the enterprise as a closely related organic whole, and closely combines the sales plan with the production plan. Together, the production plan and the procurement plan are closely combined, so that the company's own sales plan, production plan, and procurement plan are automatically integrated. It is this that enables enterprises to achieve efficient production, reduce material reserves, and save capital.

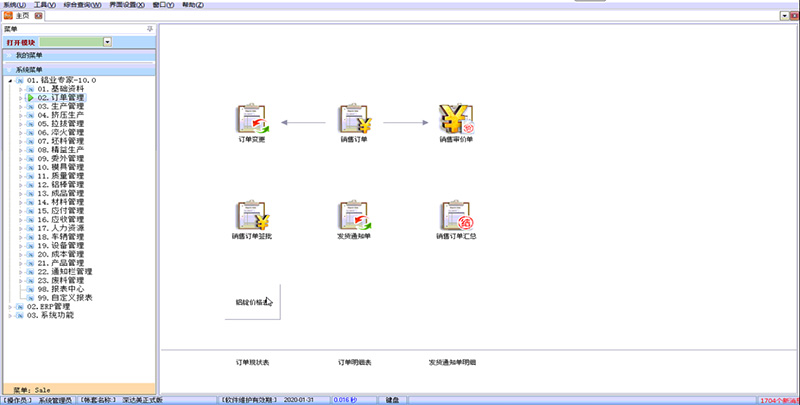

Third, the successful implementation of the aluminum industry expert 10.0

Foshan Shendamei Special Aluminum Alloy Co., Ltd. has implemented, tested and used the aluminum industry expert 10.0 system since November 2017. After more than one month, it has developed rapidly on the aluminum industry expert 10.0 platform according to the specific needs of your company. A set of ERP enterprise management systems suitable for your company.

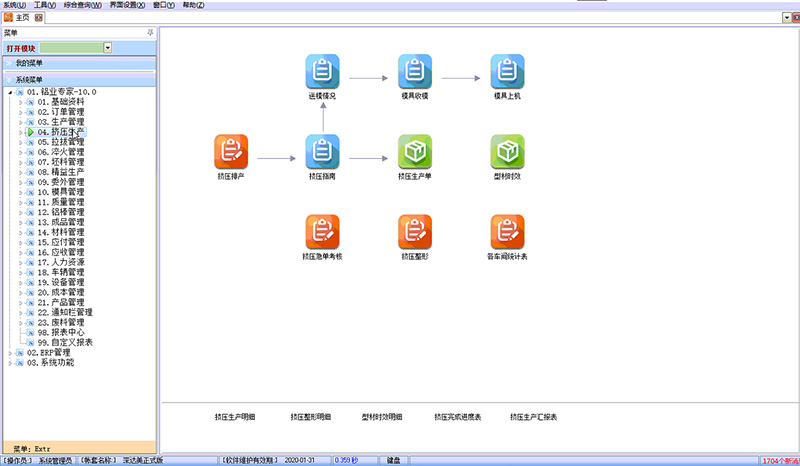

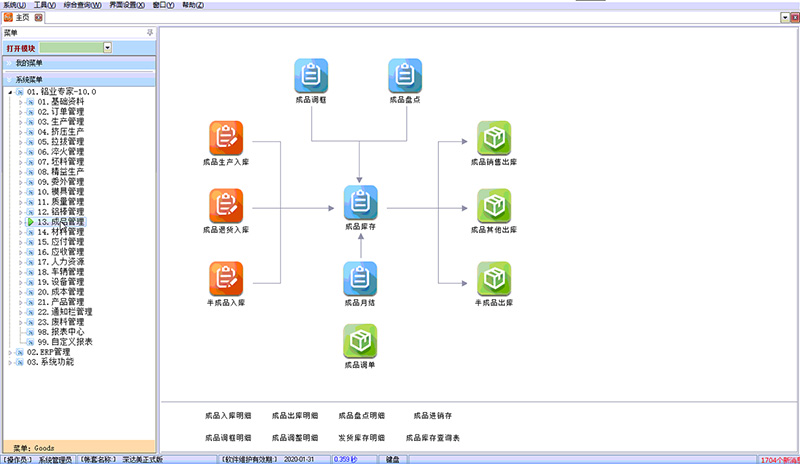

From sales orders to extrusion scheduling, extrusion completion registration, to drawing and discharging, drawing completion registration, quenching scheduling, quenching to complete registration, and finally to finished product storage, finished product delivery, cost accounting, the entire system The process is closely linked and closely connected, so that the aluminum industry expert 10.0 system is perfectly combined with the actual application of the enterprise, providing accurate and timely production planning, providing relevant reports in various links in real time, assisting employees to quickly complete work tasks, and improving the enterprise. The overall management level.

Cost accounting is a process that reflects all kinds of expenses in the production and operation process of an enterprise. It is also a process of cost information feedback for better implementation of cost management. Implementation of cost planning, cost level control and target cost realization. It plays a vital role.

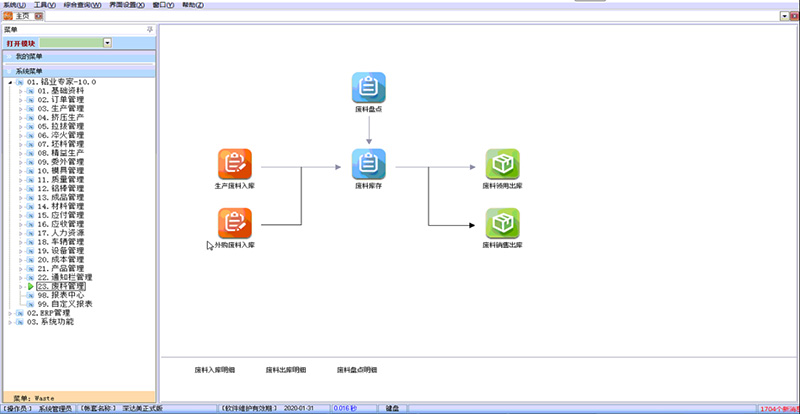

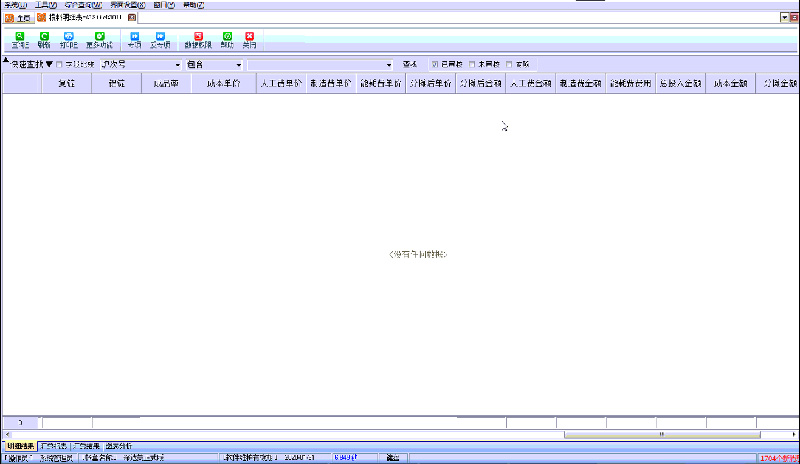

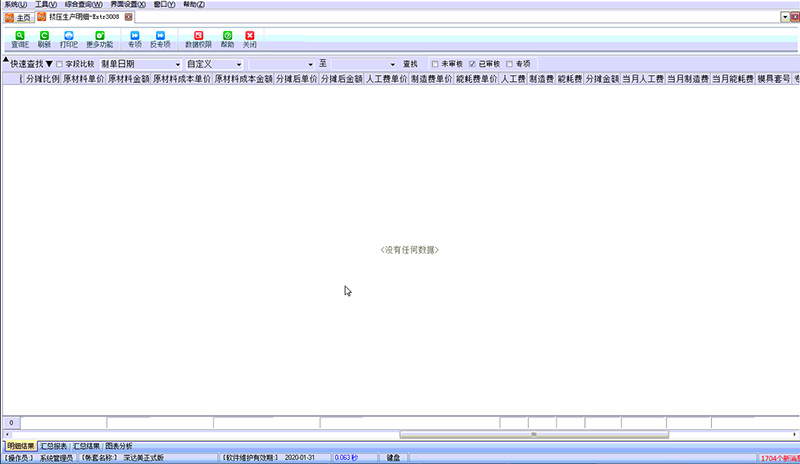

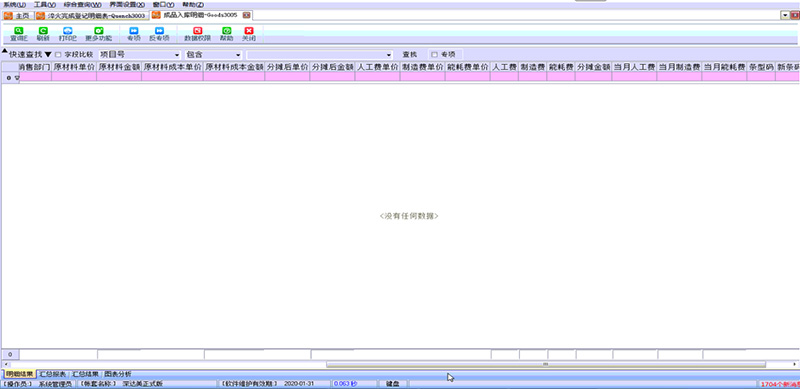

In our project of Shendamei Special Aluminum Alloy Co., Ltd., the aluminum industry expert 10.0 system uses the bar code tracking mode to apportion the expenses incurred in each production process in the entire system process. From material procurement to smelting and casting, extrusion production, to drawing, quenching, and finally to finished product storage, from unit price of raw materials to unit price of raw materials, to cost unit price after apportionment, cost unit price of each product in each production link. They are all presented in the form of a report. Among them, the labor cost, manufacturing cost, and energy consumption fee are allocated in each production workshop in a unique mode, which is an important theoretical basis for calculating the product cost in the whole system. Waste management is also an important part of the system process. In the casting and processing workshop, extrusion production workshop, drawing workshop, quenching train room, and finished product warehouse, it is possible to generate some recycled materials. These recycled materials will also be automatically generated with cost unit price. The documents are put into the warehouse and entered into the scrap stock so that they can be used again in the casting workshop.

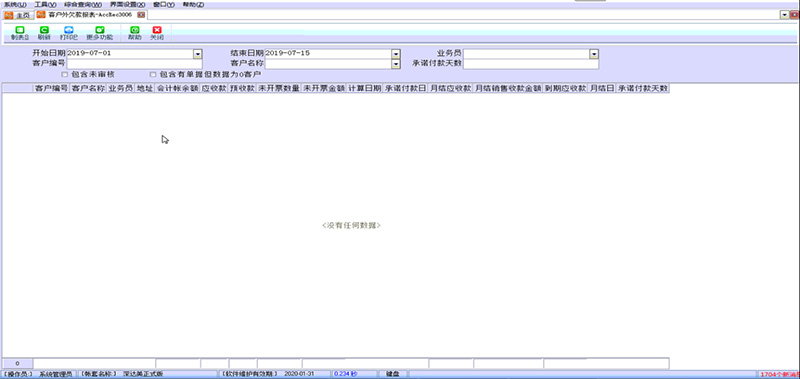

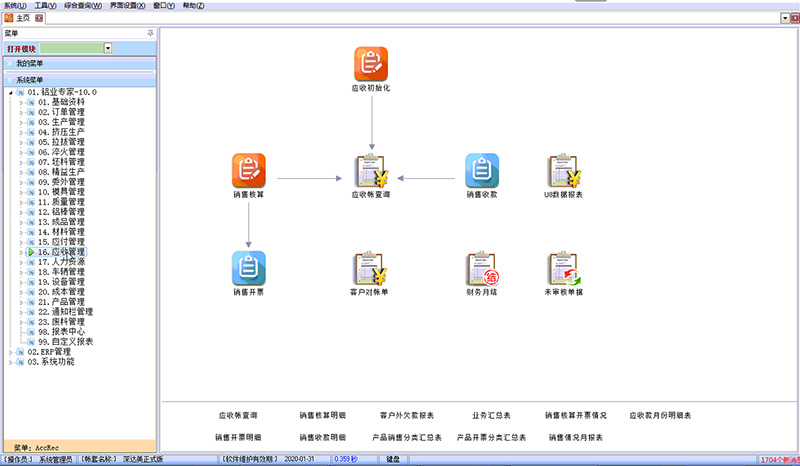

Accounts receivable is the product of each company's production and operation activities, the sale of goods and services, and is the unrecovered unit of purchase and the occupation of labor units formed by the company's credit sales of goods and labor services. Corporate funds. The credit investigation of customers is to investigate and evaluate the credit status of customers such as quality, payment ability and financial status.

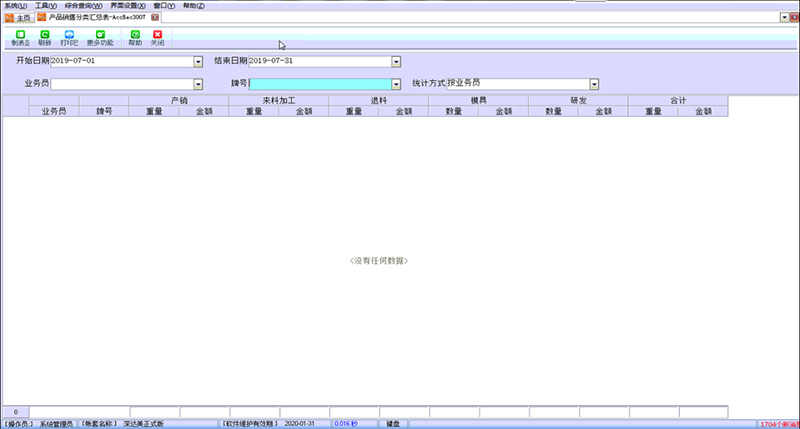

Receivable management is also a highlight of the aluminum industry expert 10.0 system. According to the monthly data date defined by the customer data, the number of promised payment days, and the conditional amount, various reports such as the customer's external debt statement, customer statement, and receivable are customized. The monthly schedule, etc., for each customer's receivables, monthly receivables, due receivables, and promised payment dates are clear at a glance. In addition, the business summary table, product sales sub-sales summary table, product billing sub-sales summary table, sales monthly report and other reports on the performance appraisal management of the salesperson can stimulate the real work of the salesman, which is conducive to better achieving the work goal. .